Shenzhen Guanheng New Materials Technology Co., Ltd., since its establishment in 2001, has been dedicated to the R&D, manufacturing, sales, and service of fluorosilicone materials.

The company is headquartered in the Guanheng New Materials Industrial Park in Shen-Shan Special Cooperation Zone, covering an area of over 30,000 square meters. The headquarters focus on product manufacturing and application technology development. Automated production lines for monomers, polymers, and compound rubbers have been established, with an annual production capacity exceeding 1,000 tons, making SZGH a world-scale producer. A subsidiary located in Shanghai is primarily responsible for basic research and new product development.

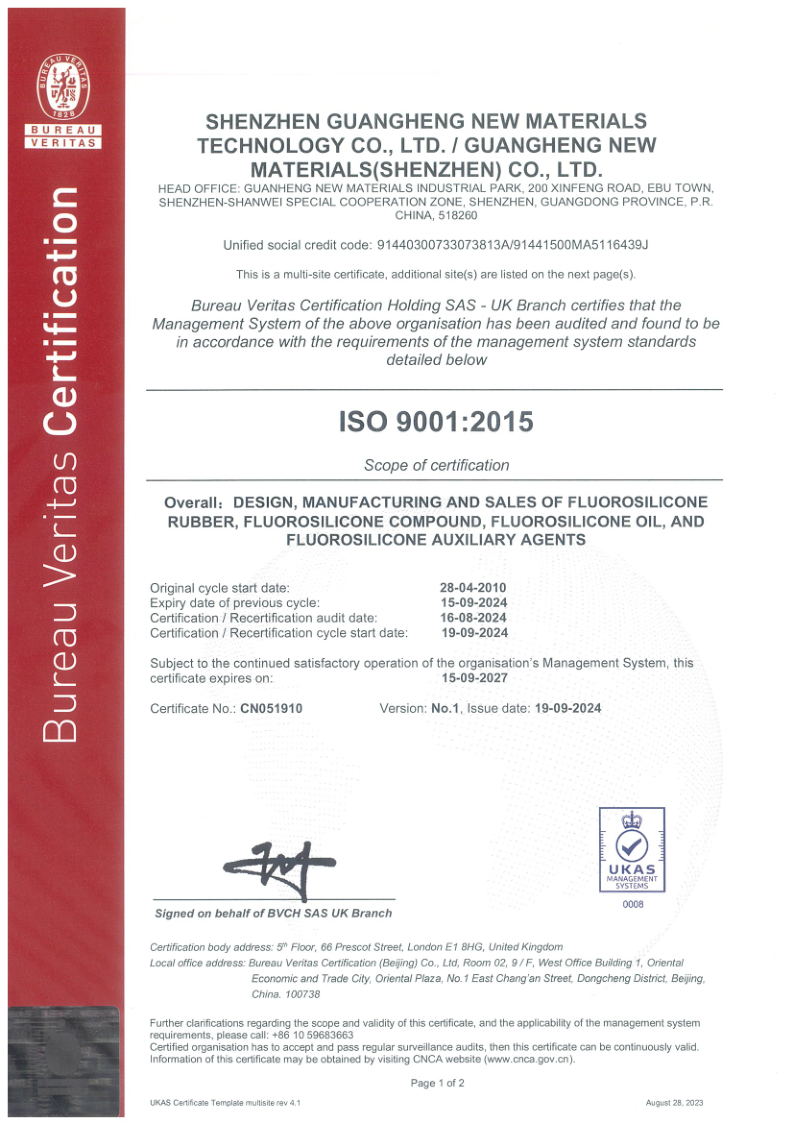

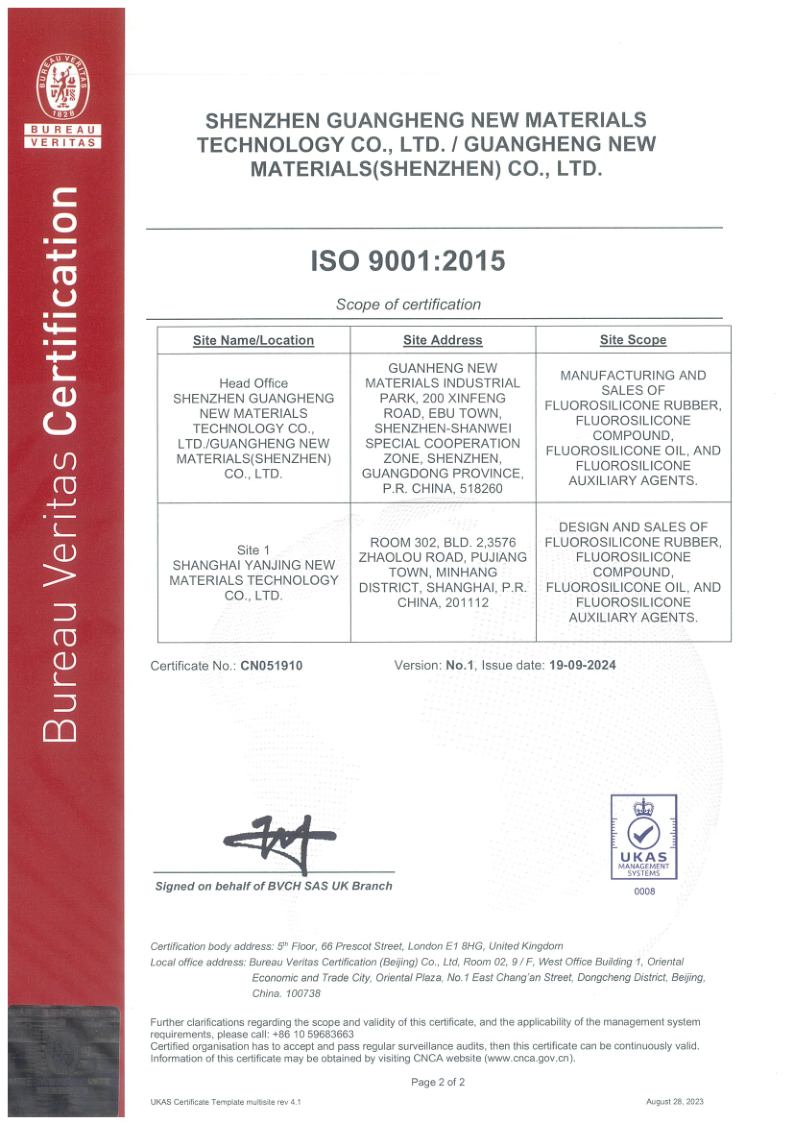

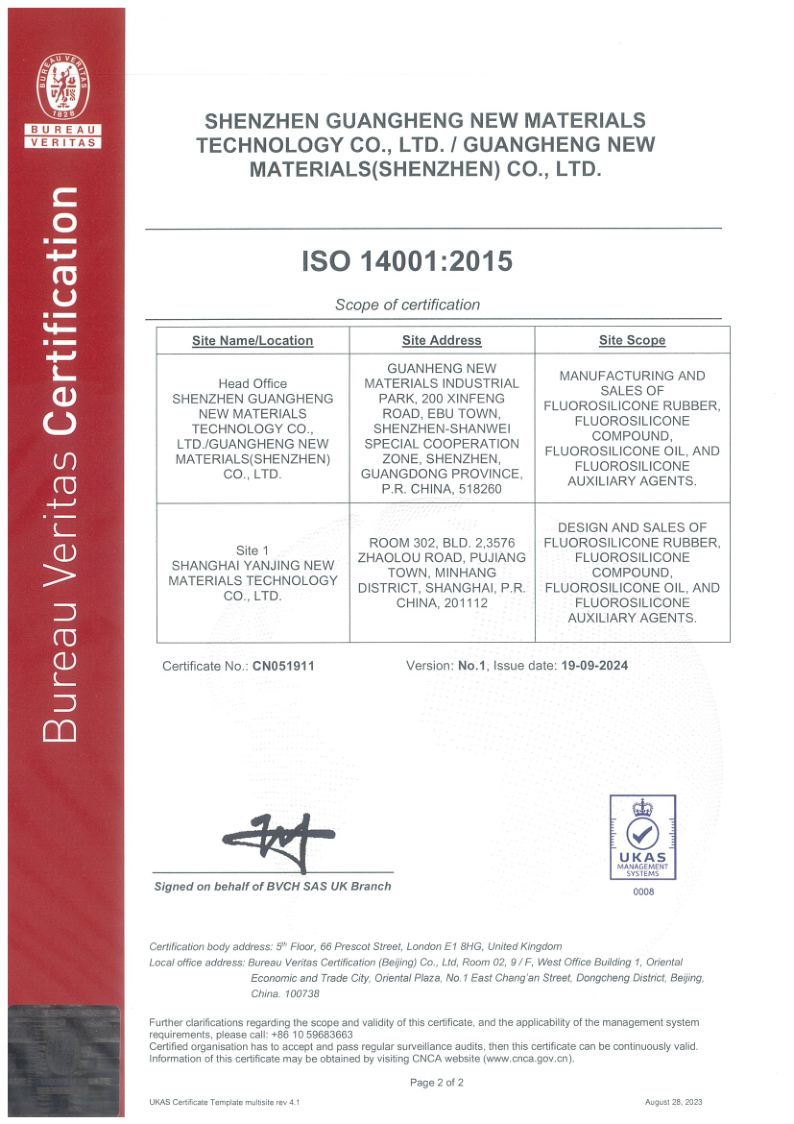

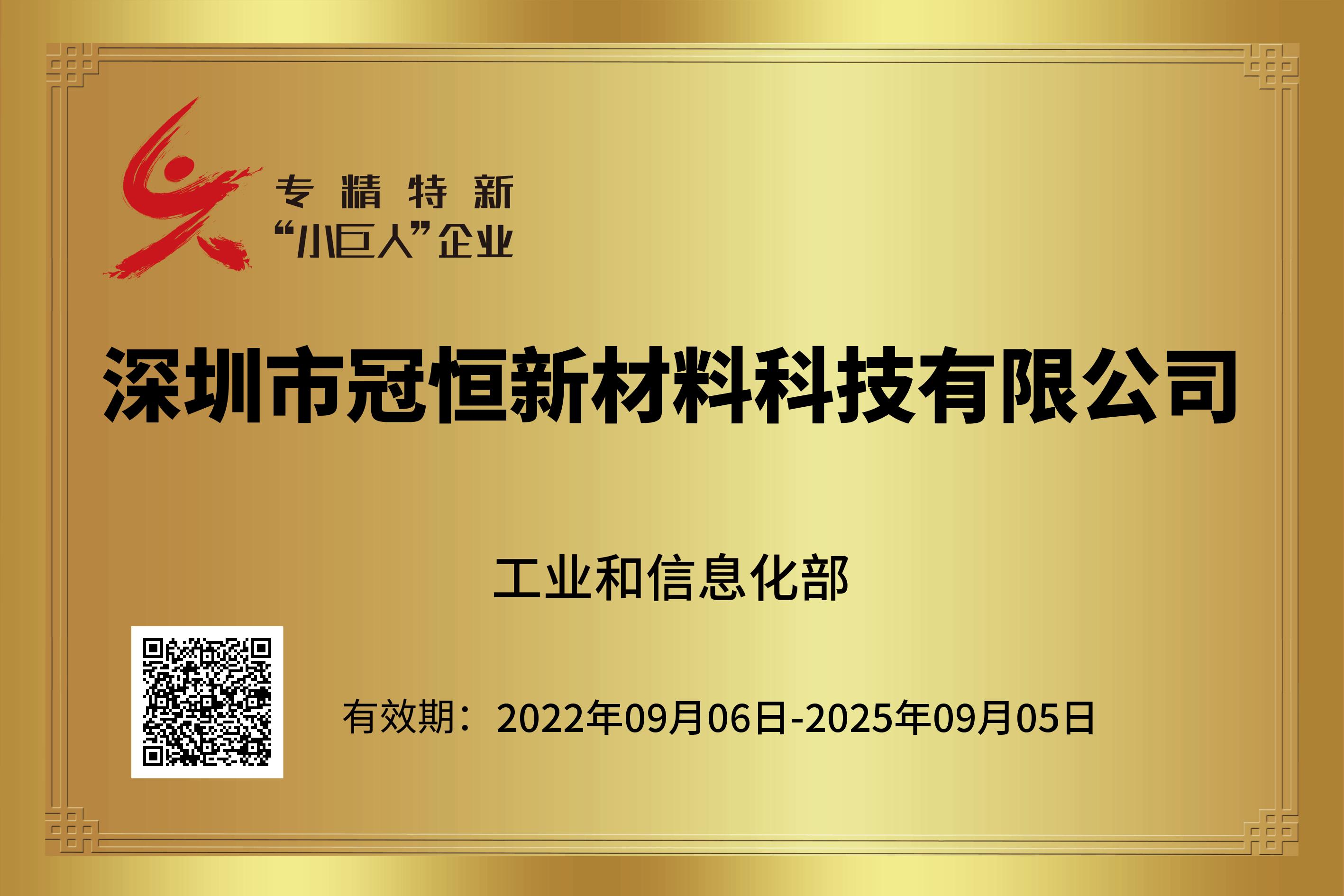

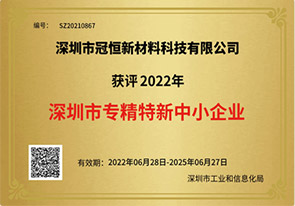

Since 2010, the company has consistently obtained ISO9001 Quality Management System and ISO14001 Environmental Management System certifications. In 2015, the products achieved compliance with the European Union's REACH regulation. From 2012 to the present, it has been recognized as a National High-Tech Enterprise four consecutive times. In 2022, the company received certifications as a "Specialized, Refined, differentiated and Innovative" SME in Shenzhen and as a National "Little Giant" Enterprise.

As a vital chemical and polymer raw material, the company's products have been widely used in industries such as aerospace, automotive, petrochemicals, healthcare, electronics, and so on. We have established extensive business relations with the distributors and end-users in domestic and foreign countries and regions.

SOCIAL RESPONSIBILITY

SOCIAL RESPONSIBILITY

ENVIRONMENTAL COMMITMENT

ENVIRONMENTAL COMMITMENT